May. 12, 2025

Vigor Technologies will bring smart production line solutions at this exhibition

Smart production line for all solid/semi-solid state batteries

The battery smart production line uses an ultra-pure inert environment system, providing a one-stop solution: automatic scanning - liquid injection/coating - weighing - packaging - stacking - slicing – testing. It has stable operation, and ensures production safety. The modular design, enables full connectivity of the production line, and make the entire process from battery preparation to packaging and testing automatic. We can customize and integrate various system equipment such as laser cutting machines, injection machines, coating machines, weighing equipment, drying systems, etc. Its excellent patent sealing effectively reduces operating costs.

Laboratory equipment for lithium sulfur battery

The laboratory equipment for lithium sulfur solid-state batteries adopts corrosion-resistant accessories and adsorption columns, and is equipped with conversion devices simultaneously. It can quickly reduce the moisture and oxygen level to less than 1ppm, and provide a ultra-low leakage rate of less than 0.001vol%/h, VOC<1ppm. The regeneration interval is long, which improves production efficiency, reduces production errors, and ensures good battery yield. Also, it ensures zero leakage of corrosive gases to guarantee the safety of experiments and the stability of equipment.

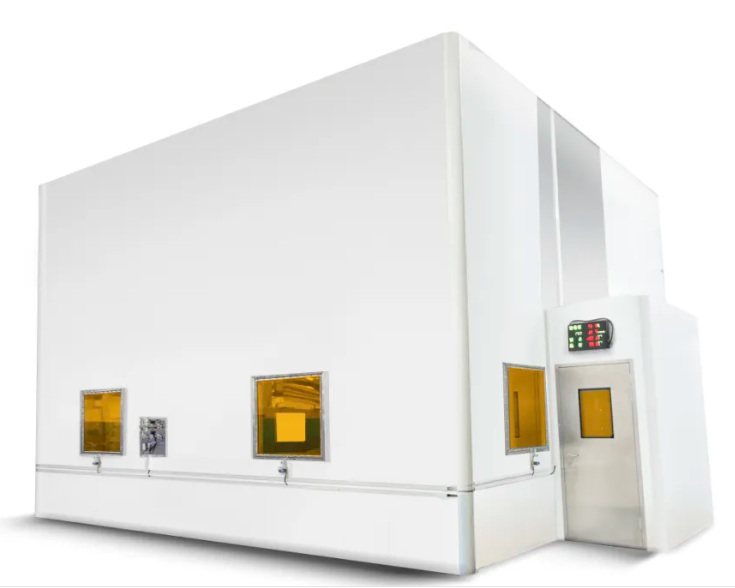

Green energy-saving drying room

The green energy-saving drying room has deep dehumidification function and can easily achieve a dew point of -65 ℃, save the energy consumption by 85%, and significantly reduce the total operating costs. It is suitable for various battery production scenarios such as large-scale production and small-scale pilot lines. Adopting leak-free sealing technology, the environment inside the box is stable, which improves the production efficiency and energy efficiency, and reduces carbon emissions. Vigor can provide diversified dehumidification options for different production environments and scales. Quickly built and durable.

Solution of smart warehousing

It can maintain a low water/oxygen environment with impurity levels<1ppm; Equipped with a central data center and WMS system, it monitors and alerts in real-time, and provides accurate feedback on data. Also, it integrates storage robots or smart shelves to meet the quality and efficiency of lithium battery production, achieving "efficient automated production". The built-in warning system in the box effectively helps managers detect problems, make adjustments, and ensure the reliable, safe, and stable operation of the system.

Vigor is committed to the development of green energy, promoting the innovation of this industry, and building smart production line solutions in the field of new energy. We always adhere to the concept of "customer-oriented demand", continuously optimize product and service experience, promote the upgrading of the new energy industry through smart production solutions, and contribute our technological strength to achieving a green and low-carbon future.

NAVIGATION

5718 Westheimer Rd, Suite 1000, Houston, TX 77057, USA